Whether you think it’s a technological flash in the pan, or a more seismic shift than the Industrial Revolution, adoption of artificial intelligence (AI) is dominating business discussions across all industries.

And the packaging industry is no exception. According to a new White Paper, 5 Ways Generative AI Will Transform Packaging by 2030, published by Smithers, in association with Empack and Packaging Innovations, generative AI (GenAI) is emerging as a major driver of growth, creativity, and efficiency across the sector in 2026.

This is great news for an industry that faces mounting pressure from sustainability regulations, accelerated time-to-market demands, and the need for personalised, on-demand production.

In this blog we discuss:

- Why old disconnected, manual workflow processes are increasingly eroding profit

- How AI and labels and packaging printing automation are reshaping the $1.2 trillion global packaging market

- Web-to-print for packaging: The solutions that driving faster product launches, smarter supply chains, and greater efficiency.

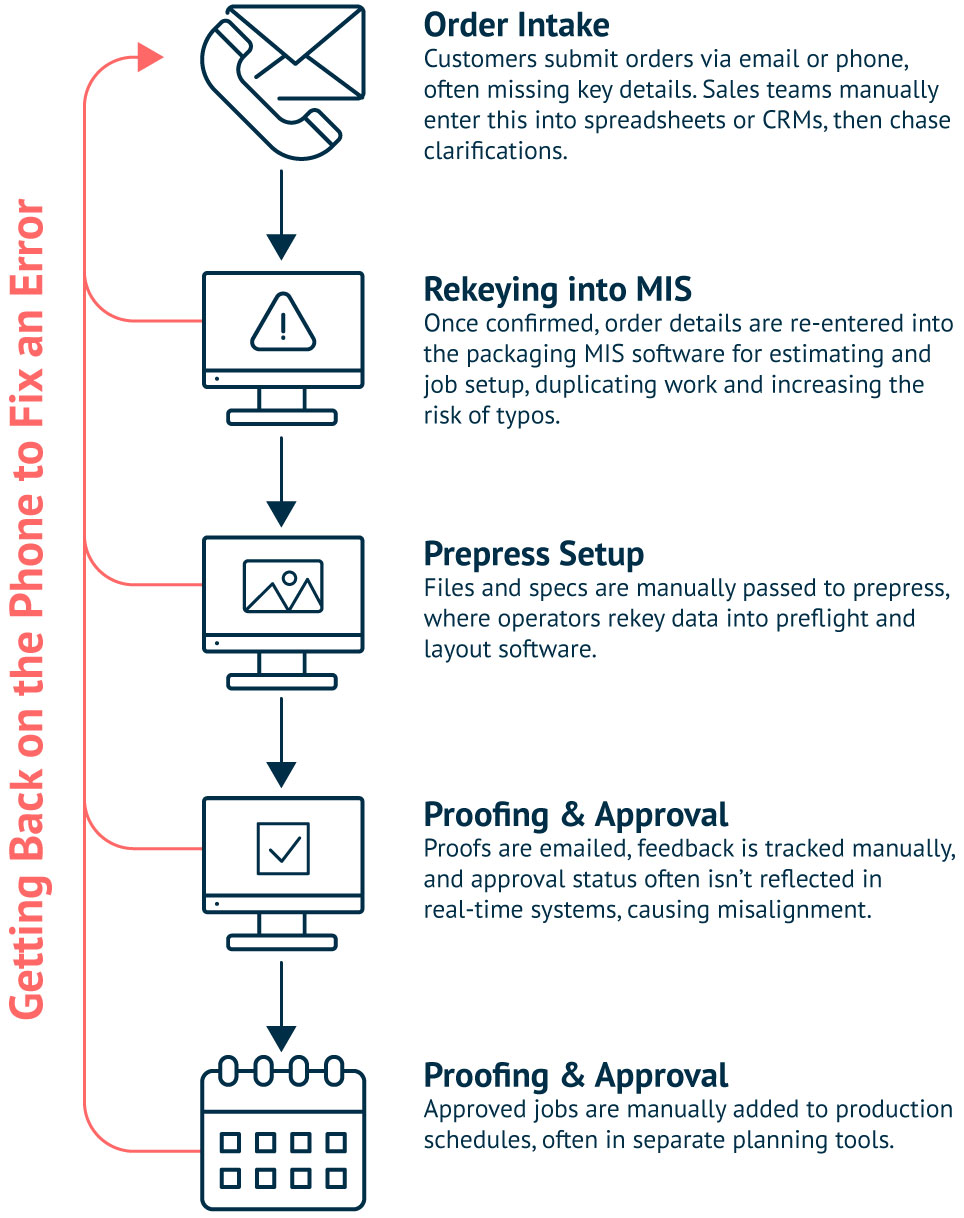

The Challenges for Traditional Packaging Workflow

Packaging businesses are under increasing pressure to deliver faster, more personalised products (at scale) without compromising quality or margin.

On top of this we are seeing:

- The rise of smaller, regional brands with more SKUs

- A need to react rapidly to fast-moving market trends, often led by social media

- Regulatory and consumer pressure to reduce waste and improve sustainability.

However, processes that worked just a few years ago are no longer able to keep up with the demands of a modern packaging supplier.

In many packaging operations, jobs move through disconnected systems, with key data re-entered multiple times, slowing production and increasing risk.

As SKU volumes rise and average run lengths shrink, these inefficiencies quickly become unsustainable especially for businesses managing multiple short-run or customised jobs.

This repetitive handling of the same information slows turnaround, limits throughput, and leaves little time for value-adding work.

The Business Case for Packaging Workflow Automation

Packaging workflow automation can reduce file preparation time by up to 80%, slash cycle counting times by 50%, and enable same-day return on investment in some implementations.

By eliminating repetitive tasks and data re-entry, teams can process more jobs in less time, without increasing headcount.

This is because automation connects every stage of the process, from online order entry to prepress, production and delivery. A seamless flow of data minimises delays, ensures consistency, and frees up skilled staff to focus on value-adding tasks rather than admin.

Crucially, automation also supports future-facing trends.

AI-powered demand forecasting, intelligent packaging with embedded tracking, and right-sizing technologies all rely on structured, real-time data. Without integrated systems, these innovations are hard to scale.

This is why Generative AI is increasingly being explored to simplify and reduce the cost of artwork creation. By 2030, Smithers forecasts that GenAI will be embedded across creative, administrative and production processes – from artwork to logistics.

To remain competitive, businesses need streamlined, automated systems across with the workflow, driven by the latest developments in AI.

Why Packaging Workflow Automation Matters

Many packaging businesses already operate with MIS, prepress tools and digital print equipment. But inefficiencies arise when these systems are disconnected.

As we have already mentioned, common issues include:

- Manually re-entering order data

- Repetitive prepress tasks and proofing

- Lack of visibility across departments

- Approval delays and inconsistent job specs

The Benefits of Integrated Workflow Automation

With shorter runs and increasing SKUs, these manual steps become costly bottlenecks.

Smithers notes that packaging operations must adapt to fulfilment models that demand smaller, more frequent runs, particularly in e-commerce.

When systems work together, businesses gain:

- Higher throughput: More jobs processed per shift, without increasing headcount

- Lower error rates: Standardised data handling reduces costly rework

- Faster cycle times: From order to press, jobs move quicker through the system

- Smarter resource use: Skilled staff focus on exceptions, not admin

AI-powered optimisation and smart packaging lines also depend on structured, connected data. Automation isn’t just about speed, it’s about building a foundation for long-term agility and insight.

Why Integration Is Key: From Web-to-Print to Press

True efficiency comes from treating web-to-print, MIS and prepress not as separate systems but as a single, connected workflow. A workflow that provides an End-to-End Ecosystem for Packaging Print.

An End-to-End Ecosystem for Packaging Print

By combining:

- Infigo for configurable web-to-print storefronts

- CERM for packaging-specific MIS

- Hybrid Software with CLOUDFLOW and Proofscope for prepress automation

Businesses like yours can create a connected ecosystem designed specifically for packaging and label production.

Rather than relying on one-off scripts or manual file handling, this setup uses open standards (like JDF/JMF) to exchange data reliably and in real time, from order entry to production.

Breaking It Down: What Each Platform Delivers

Infigo: Web-to-Print for Packaging

Infigo provides the online storefront whether for brand portals or trade ordering. Key capabilities include:

Template-based design and custom configurators

Customers can create print-ready designs with ease. Whether starting from a professionally designed template or using advanced configurators for bespoke layouts, the process is intuitive, consistent, and fast, reducing time-to-order and increasing customer satisfaction.

Controlled personalisation and artwork upload

Brand integrity is maintained, while offering flexibility. Controlled personalisation ensures users can customise only the approved areas, minimising errors and off-brand designs. Artwork uploads are streamlined and secure, giving users confidence while preserving production efficiency.

Automated spec validation at the point of order

Costly reprints and production delays are massively reduced, if not eliminated. With real-time validation of artwork spec (such as file format, resolution, bleed, and margins) orders are checked and approved instantly. This automation ensures files meet production standards before they ever hit the press.

By capturing accurate data upfront, Infigo reduces downstream errors and admin effort.

CERM: MIS Built for Packaging

CERM manages job creation, estimating and scheduling, with features tailored to roll-fed, sheet-fed and wide-format operations:

Real-time cost estimating

Real-time estimating gives your team instant visibility into accurate, margin-protected pricing—helping you respond faster, win more work, and maintain profitability on every job. Accurate quotes are provided in seconds, rather than hours.

Substrate and tooling management

You gain full control over substrates, dies, and tooling with real-time availability and automated tracking. This this ensures the right materials are on hand and aligned with production requirements. Inventory is streamlined and waste is significantly reduced.

Production data collection and job tracking

Real-time data capture and job tracking provide end-to-end visibility across every production stage, improving efficiency, flagging delays early, and enabling smarter resource planning.

Seamless integration with Infigo and prepress tools

With plug-and-play integration to Infigo and leading prepress systems, you reduce manual touchpoints, accelerate job setup, and ensure data flows accurately from web-to-print through to production.

In short, CERM turns order data from Infigo, into structured job information, ready for production.

Hybrid Software: Prepress Automation

Hybrid’s CLOUDFLOW and Proofscope platforms automate and streamline prepress:

Preflight and file normalisation

Automated preflight checks and file normalisation ensure every incoming file meets technical and print-ready standards—reducing manual intervention, rework, and delays on press.

Colour management and step-and-repeat layouts

Automated colour calibration ensures brand consistency across substrates, while intelligent step-and-repeat layouts optimise sheet usage—saving time, reducing waste, and improving output quality.

Browser-based proofing and approval workflows

Clients and stakeholders can review, annotate, and approve proofs from any device—eliminating email chains, reducing approval cycles, and increasing transparency.

Live status updates back to the MIS

Real-time feedback from pre-press to your MIS gives sales, planning, and production full visibility into job readiness—supporting better scheduling, fewer bottlenecks, and a smoother end-to-end workflow.

This reduces repetitive prepress work and ensures consistency across every job.

The Workflow in Action: From Order to Output

So how does a typical job move through the integrated workflow?

Online Order: A customer configures a packaging product in the Infigo storefront, selecting options and uploading artwork.

Job Creation: Infigo passes structured order data to CERM, which creates the job, links it to tooling, and estimates cost and time.

Prepress Setup: CERM sends JDF job instructions to CLOUDFLOW. Files are preflighted, colour-corrected and proofed automatically.

Approval & Production: Proofscope enables browser-based approval. Once approved, the job is marked production-ready and scheduled for press.

Throughout, no one rekeys data, no files are emailed back and forth, and every stakeholder has visibility over job status.

Real-World Benefits: Across the Business

An integrated workflow delivers measurable benefits across every department. For Operations and Production teams, it means reduced lead times, shorter job queues, increased throughput, and fewer production errors or reworks.

IT and Systems teams benefit from a standardised, scalable architecture that lowers integration risks, reduces maintenance demands, and simplifies onboarding of new systems or partners. Senior leadership gains improved labour efficiency, tighter alignment between job costing and actual production, and a clear roadmap toward sustainability and data-driven optimisation.

Prepress and supervisory staff spend less time on repetitive tasks and more on creative, high-value work, supported by clearer collaboration with commercial teams.

Meanwhile, Customer Service and Sales enjoy greater order accuracy, faster turnaround times on proofs and updates, and stronger support for agile campaigns and promotional activities.

The Future of Packaging Workflows: Powered by AI

Today’s workflow automation is more than just a productivity boost, it’s the foundation for tomorrow’s AI-enabled packaging.

According to Smithers, the future of the industry will be shaped by the rise of generative AI and intelligent agents, enabling capabilities such as virtual packaging prototyping, bespoke and localised artwork at scale, AI-enhanced MIS for smarter scheduling and planning, and live, data-driven packaging lines that can respond dynamically to demand.

But to unlock these innovations, structured and connected data is essential. That process begins with integrated platforms like Infigo, CERM, and HYBRID, which lay the groundwork for intelligent, future-ready packaging operations.